About Industrial Welding Inspection

Wiki Article

The smart Trick of Welding Inspection Service That Nobody is Talking About

Table of ContentsThe Ultimate Guide To Welding Inspection Service9 Simple Techniques For Industrial Welding InspectionWelding Inspection Service Fundamentals ExplainedThe Single Strategy To Use For Industrial Welding InspectionNot known Details About Welding Inspection Service Things about Industrial Welding Inspection

Here are some of the examinations that are executed at fabrication shops to ensure weld quality. Aesthetic Weld or Fabrication Evaluation It is very important to deal with a welding and construction store that performs visual weld assessments. Throughout an aesthetic weld assessment, business will evaluate products prior to beginning the weld, constantly evaluate the quality of the weld and products throughout the welding, check the end product when the weld is completed, and fix any problems that the last product could have.

Aesthetic evaluation of the completed welded item will typically involve welders examining to make certain that the typical weld mistakes are absent in the weld, inspecting the finish and shape, verifying that the item size matches that of the prints, and also inspecting to guarantee that the weld is lined up with welding criteria.

The 10-Minute Rule for Industrial Welding Inspection

Speaking with potential welding and fabrication shops will certainly give you a feeling of whether they actually care about what they do and the high quality of their job. Call a Dependable Quality Welding & Fabrication Shop Near You If you are in search of a high quality welding as well as fabrication shop in the Everett location, look no more! Eckstrom Industries was started in 1930 as well as has been servicing the better Seattle area since.Aesthetic assessments, or Visual Testing, is the most well understood and also basic method of assessment. Visual Inspection requires no equipment except a qualified examiner with an eager eye.

Visual Inspection little to no technology contrasted to various other forms of assessments. In spite of this, it improve a number of benefits over more sophisticated inclined inspection approaches. Visual Evaluation is basic contrasted to various other methods, and is even more budget-friendly for smaller budgets. This is very due to Aesthetic Examinations not needing equipment.

Industrial Welding Inspection - Truths

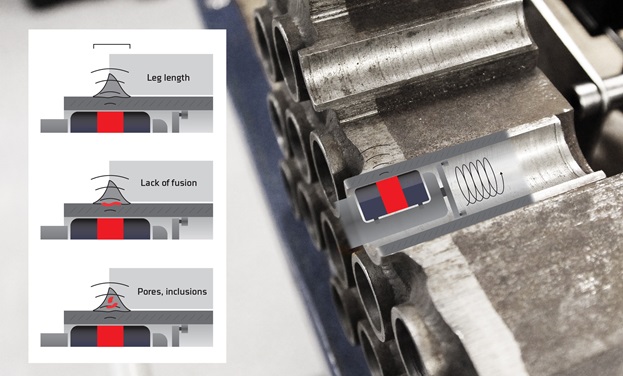

Contents What are welding evaluation as well as testing? Welding assessment is to check or understand attributes a weld has as well as to examine stoppages in the weld. The size of a weld is very crucial as its strength as well as efficiency can be determined. It is great to understand the performance of a weld and to understand if it might or may not withstand stresses used throughout service.

Suspensions are recognized as welding issues, and they cause premature weld failure because of included anxiety concentrations or decrease of toughness within the bonded part. Industrial Welding Inspection. Evaluating the top quality of a weld, there should be some requirements to which the weld features can be compared. There are phases some weld suspensions can be accepted depending on the appropriate top quality for its desired application.

How Industrial Welding Inspection can Save You Time, Stress, and Money.

It is also indicated to dictate the degrees of welds suspensions if they can be approved. It is necessary to choose as well as adhere to a welding standard that is put on a certain application with sector as well as understand if the intended objectives are fulfilled. The acceptance requirements quality of welding can be come from can be obtained from several resources (Industrial Welding Inspection).There are numbers of training courses readily available internationally, but the most popular program utilized in the USA is administered by the American welding culture (AWS). What are the Weld examination methods The list below stated below are different techniques of checking welds; aesthetic inspection is most common, simplest as well as the least pricey method of inspecting a weld.

these evaluation methods are made use of to detect fine cracks, porosity, seams, and various other surface-breaking welding discontinuities. Surface crack detection can be achieved in two ways; liquid penetrant evaluation or magnetic bit examination. these approaches are referred to as They are performed to check the high quality and also discontinuities of the weld without damaging the bonded element.

The 30-Second Trick For Welding Inspection Service

Damaging weld screening is additionally done to examine the quality of welds. It should be after the analysis of complete weld high quality need and acceptance requirements.Welding is a bonding together or coalescence of two similar or dissimilar steel/ metal products attaining a toughness equivalent to or more powerful than the steel base metal. In a building structure, it provides connections of steel light beams, columns and steel plates strengthen the area required for solution. The welding is carried out in the manufacture store as well as or in the area - Industrial Welding Inspection.

Examine the steel material mill certs, filler metal and equipment setups per welding treatment specification. Steel is the structural sturdiness and also stability of the building. If welding is not done by code or treatment it could result in malfunctioning job which would lead to the removal of weld locations by grinding and also re-welding.

Welding Inspection Service Fundamentals Explained

At the extremely the very least, the customer may experience a situation where cash can be conserved by making adjustments to a pipe that was identified in advance if a well-informed SWI was a https://www.cwiweldinginspector.com component of construction. What does a common day or job resemble for you? A normal day for one project consists of: Lead daily/weekly production conferences with the professionals to go over task progression and also any concerns.Review daily as-built reports submitted by level 13 inspectors. Testimonial daily weld and construction reports from inspectors. Monitor and routine qualification screening for potential welders for professionals. Review weld procedures and select the applicable procedure for each and every project/situation. Validate welders that have previously evaluated for the professional still have appropriate accreditations.

Report this wiki page